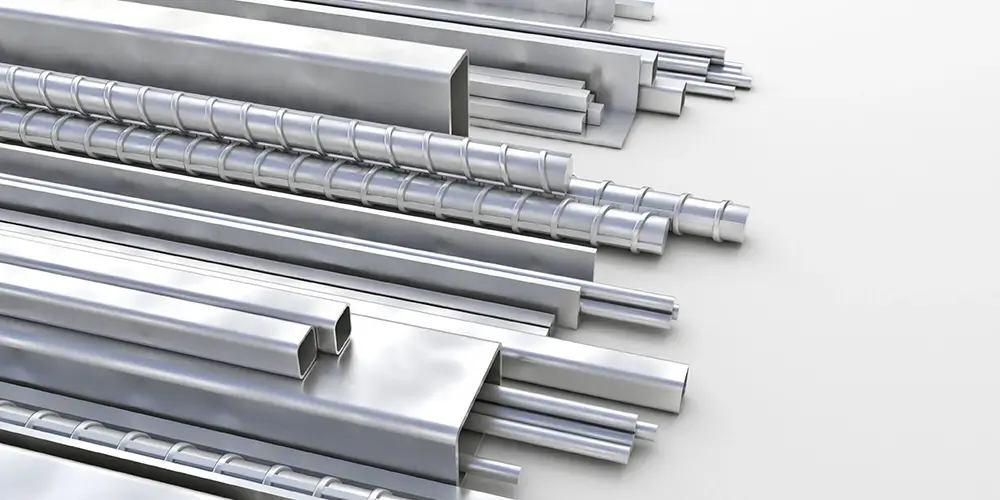

When purchasing structural steel, it's crucial to consider factors beyond just price. The integrity, strength, and longevity of your project depend on choosing the right material. As a seasoned expert in the steel industry, I’ve seen how selecting the wrong type of steel can lead to structural failures, increased maintenance costs, and compromised safety. To ensure you make the best choice, here are the key factors to evaluate when buying structural steel.

1. Steel Grade and Composition

The grade of steel you select determines its strength, ductility, and weldability. Structural steel is typically graded according to its mechanical properties, including yield strength, tensile strength, and hardness. The most commonly used grades include ASTM A36, A572, and A992.

- ASTM A36: Known for its good weldability and machinability, A36 is a standard choice for structural applications but may not be the best for high-stress situations.

- ASTM A572: This high-strength, low-alloy steel offers enhanced strength-to-weight ratios and is preferred for heavier constructions like bridges and high-rise buildings.

- ASTM A992: Often used in the construction of I-beams and wide flanges, A992 steel offers excellent weldability, along with a combination of high strength and ductility.

Consider the specific requirements of your project, such as load-bearing capacity and environmental conditions, before selecting the steel grade. Always check the mill test certificates to verify that the steel meets the required standards.

2. Steel Quality and Certifications

Ensure that the steel you purchase comes from a reputable manufacturer who adheres to industry standards. Look for certifications from recognized bodies like the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO). These certifications guarantee that the steel has been produced under strict quality controls and meets the necessary specifications for structural use.

Beware of counterfeit products or substandard steel from suppliers who might cut corners to offer lower prices. Always request and verify material test reports (MTRs) from the supplier, which should detail the steel's chemical composition and mechanical properties.

3. Surface Finish and Coatings

The surface finish of structural steel is not just about aesthetics; it plays a crucial role in the steel’s resistance to corrosion and environmental damage. Structural steel exposed to outdoor environments or corrosive conditions should have a protective coating, such as galvanization, to prevent rust.

- Galvanization: A zinc coating applied to steel provides a durable, corrosion-resistant finish that can extend the life of the steel by decades, even in harsh environments.

- Primer Coatings: For projects requiring painting or additional finishing, a primer coating ensures better adhesion and longer-lasting protection.

- Mill Scale: Be cautious of steel with heavy mill scale, a flaky surface layer formed during hot rolling. Mill scale can impede paint adhesion and accelerate corrosion if not properly treated.

Choose steel that has been properly treated and finished to suit the environmental conditions of your project site.

4. Dimensional Accuracy and Tolerances

Structural steel must adhere to precise dimensional tolerances to ensure it fits seamlessly into the design and structure of your project. Check the steel for straightness, squareness, and uniformity in thickness and width. Tolerances should comply with standards like ASTM A6/A6M, which specifies the permitted variations in shape, dimensions, and weight.

Any deviations from these tolerances can lead to misalignment during construction, increased labor costs, and potential structural weaknesses. Make sure to inspect the steel upon delivery to verify that it meets the required specifications and tolerances.

5. Weldability and Workability

Another critical factor is the ease with which structural steel can be welded and worked. The steel’s carbon content, along with its alloying elements like manganese, sulfur, and phosphorus, influences its weldability. Low-carbon steels generally offer better weldability, while high-carbon steels may require preheating or post-weld heat treatment to prevent cracking.

Additionally, consider the steel’s workability, which includes its ability to be cut, bent, and drilled without losing structural integrity. Steel with high workability reduces labor costs and ensures faster project completion.

6. Sourcing and Supply Chain Reliability

The reliability of your supplier is just as important as the quality of the steel. Work with suppliers who have a proven track record of delivering high-quality materials on time. Delays in the supply chain can cause significant setbacks to your project timeline and budget.

It’s also worth considering where the steel is sourced from. Domestic steel might offer better quality control and faster delivery, while imported steel could be more cost-effective but might present challenges in terms of quality assurance and lead times.

7. Environmental Impact and Sustainability

As the construction industry moves towards more sustainable practices, the environmental impact of the materials you use becomes increasingly important. Look for steel that has been produced using environmentally friendly processes, such as electric arc furnace (EAF) steelmaking, which has a lower carbon footprint compared to traditional blast furnace methods.

Consider suppliers who offer steel with a high recycled content or who participate in sustainability programs like LEED (Leadership in Energy and Environmental Design). Using sustainable steel not only benefits the environment but can also improve your project's eligibility for green building certifications.

8. Cost vs. Long-term Value

While it’s tempting to choose steel based on upfront cost, it’s essential to consider the long-term value. Higher-quality steel may come with a higher price tag, but its durability, resistance to corrosion, and reduced maintenance requirements can result in lower overall costs over the life of the project.

Consider the total cost of ownership (TCO), which includes not just the initial purchase price, but also the costs associated with maintenance, repairs, and potential downtime due to material failure. Investing in high-quality structural steel can save you money and headaches in the long run.

Choosing the right structural steel is a complex decision that requires careful consideration of various factors, from material grade and quality to supplier reliability and environmental impact. By paying attention to these details, you can ensure that your project is built on a solid foundation that will stand the test of time. Always consult with experts and industry professionals when making your selection to guarantee that you’re using the best possible materials for your structural needs.

Contact us for better guidance and the steel that meets your requirements!